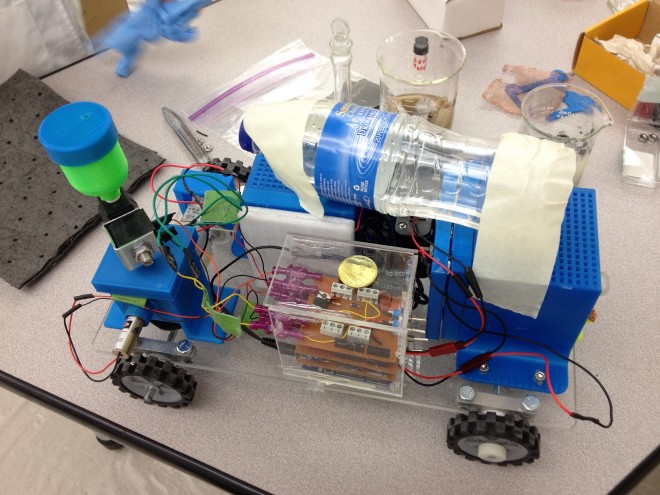

UBC Chem-E-Car’s vehicle “Plastic Metals” at competition at Washington State University, April 2014. Many of the parts were fabricated using 3D printing by UBC Rapid. The water bottle holds the competition required payload. A shiny loonie is placed on the electronics for good luck.

In 2013, the UBC Chem-E-Car built an innovative shoe-boxed sized car that could chemically produce, store and utilize hydrogen (using a fuel cell) on-board the vehicle. This year, Chem-E-Car turned their heads towards zinc-air batteries as a fuel source for their vehicle. Metal-air batteries have a significant weight advantage over traditional batteries, in that metal-air batteries only require storage of one metal since oxygen from air is used instead of a second metal. Additionally, the end of life product from zinc-air batteries (zinc oxide) has minimal environmental concerns and doesn’t pose health concerns; in fact, zinc oxide has many applications ranging from rubber and corrosion prevention in nuclear reactors to breakfast cereal and baby powder. Zinc-air batteries have been used in hearing aids for decades and are starting to be found in larger sizes as well.

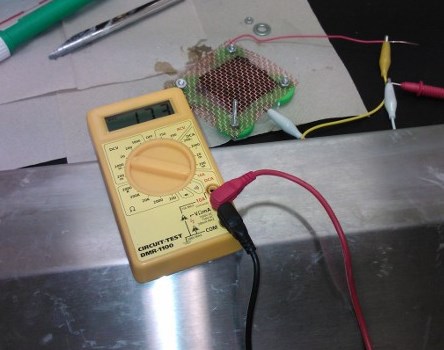

One of the first prototype batteries designed and built by undergraduate students.

One of the first prototype batteries designed and built by undergraduate students.

The battery casings and housings were entirely student designed. A collaboration with UBC Rapid (an undergraduate design team that builds 3D printers) led to most of the car’s components, including the battery casings and housings, being manufactured using minimal waste and fast turn around 3D printing methods.

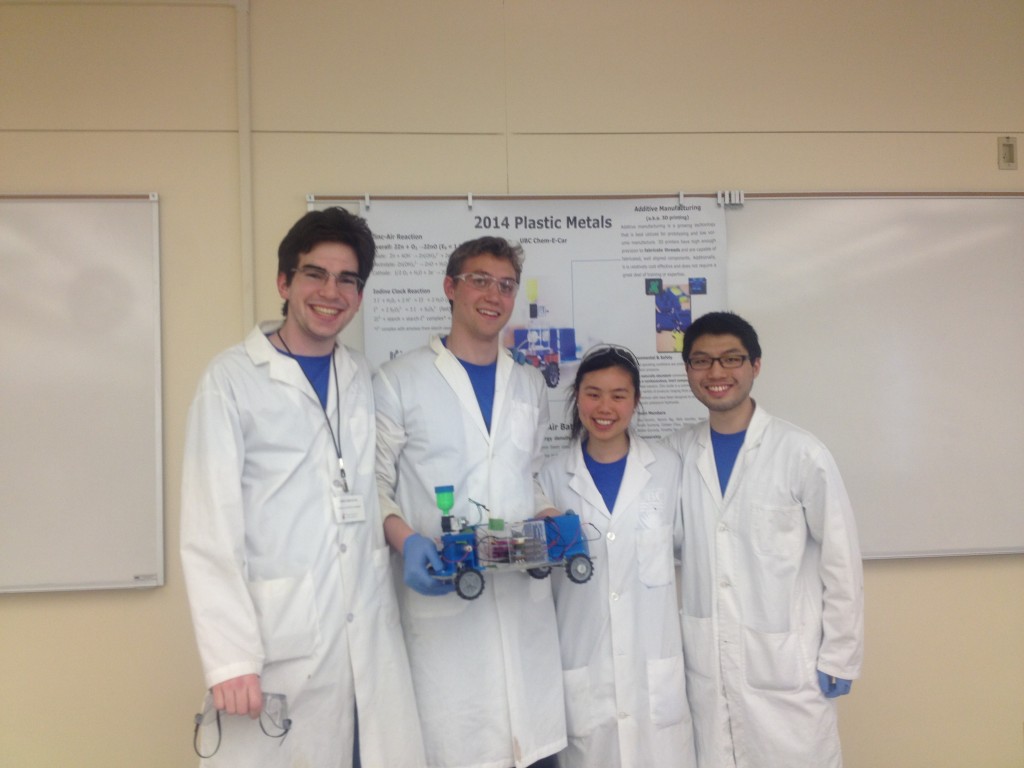

The team participates in a competition where students must control a chemical reaction to stop the car at a certain distance while carrying a payload; the catch is that the distance and payload are only given 1 hour before competition – during this hour the students must calculate the amount of chemicals to be added, prepare the chemicals for the car (in UBC’s case, this includes building batteries) and prepare the car for the race. In April 2014, UBC Chem-E-Car’s zinc-air batteries powered the car to a 1st place finish at the Pacific Northwest Regional AIChE Chem-E-Car Competition, stopping

only 39.5 cm from the finish line (meters closer than the nearest competitor). The team qualified for the AIChE National Competition where they will be spreading knowledge of zinc-air batteries while competing with 31 other teams from across North America.

only 39.5 cm from the finish line (meters closer than the nearest competitor). The team qualified for the AIChE National Competition where they will be spreading knowledge of zinc-air batteries while competing with 31 other teams from across North America.

UBC team members at Washington State University after placing 1st at the PWNR Chem-E-Car competition. (left to right: Adam Johnson, Joel Kumlin, Colleen Chau, Norvin Ng)